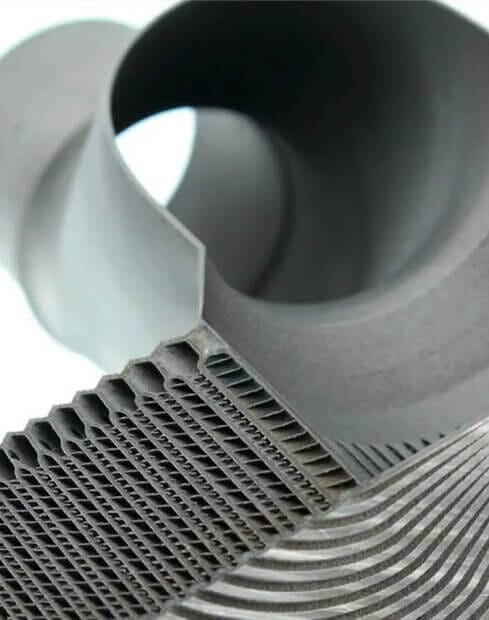

Metals, Polymers, Ceramics and Composites, materials science is a part of engineering that involves discovering and designing new materials

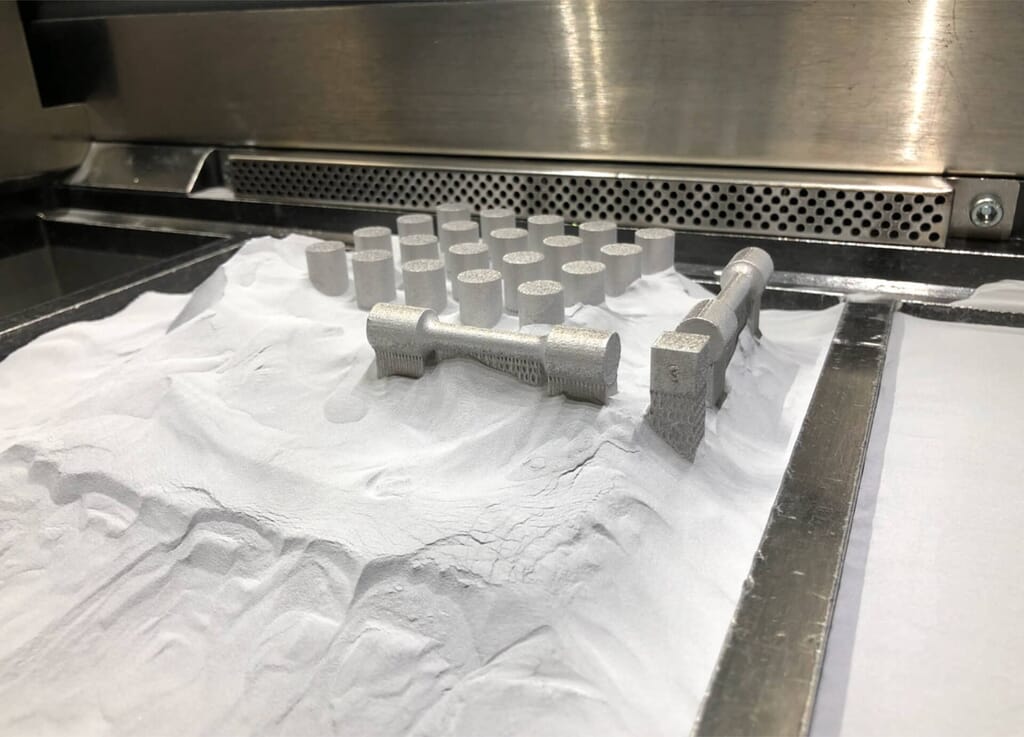

At AnyShape we not only help you select the correct material for the application, but also help in the area of custom material development relating to specific additive manufacturing powder compositions.

This area of work opens up huge opportunities for our clients, especially those involved in researching solutions for harsh environmental conditions such as 3d printing used in aerospace, space and additive manufacturing for oil and gas exploration equipment. When high strength, high temperature, creep and chemical resistance make the difference between a part performing or failing, sometimes an “off-the-shelf” solution is not an option. AnyShape can help you find the right additive manufacturing mechanical properties to make your project a success

Since 2018 AnyShape has been an approved and certified member of the Scalmalloy® distribution and manufacturing program of APWORKS GmbH (a subsidury of Airbus) Read more about the unique material properties of Scalmalloy® here