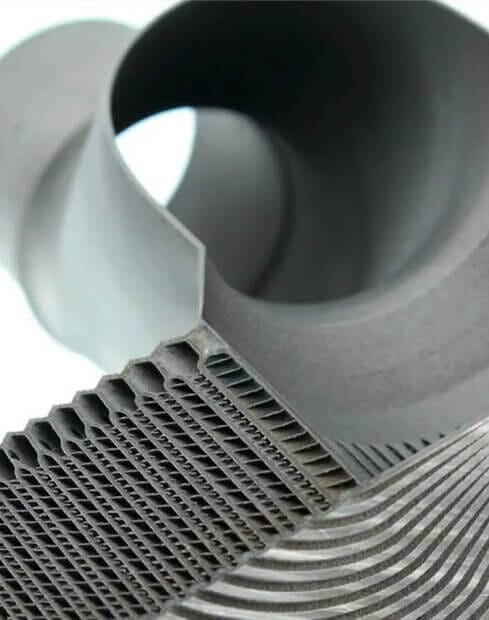

Tooling (with conformal cooling channels) Forming Tools and Serial Part Production

Just some of the well-known and proven applications firmly established amongst industrial manufacturers

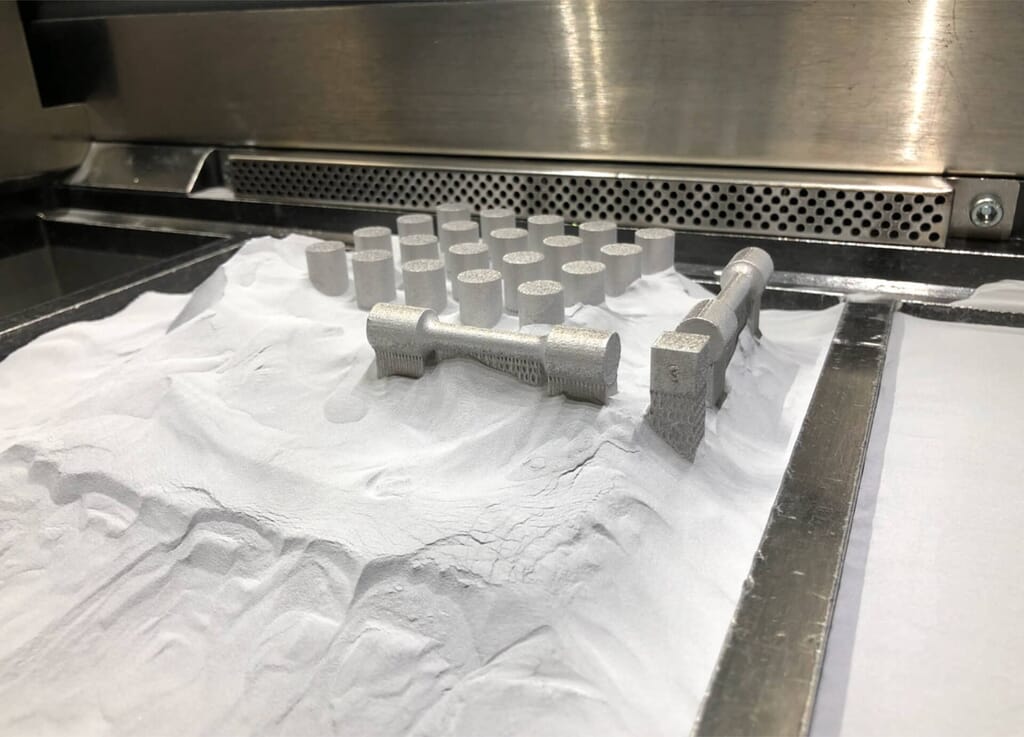

Additive manufacturing technologies are becoming faster, more cost effective and thanks to AnyShape more accessible. Our list of 3d printable metals keeps on growing but we also develop custom powder materials as part of our qualification work for global aerospace and defence customers

AnyShape sources only the highest quality additive manufacturing metal powders from the most recognized and reputable worldwide metal powder suppliers. Whether you need a bespoke lightweight bracket made in titanium, a batch of production parts produced in aluminium or a one-off custom injection mould tool with 3d printing with metal inserts.

At AnyShape we have a solution

Steels

Steel is an alloy of iron and carbon with a carbon content of up to 2%.

With a content higher than 2% the material is defined as cast iron. Any-Shape 3d prints parts in a number of steel and steel derivatives to cover most industrial and commercial applications

Aluminium Alloys

Aluminium Alloys are alloys in which aluminium (Al) is the predominant metal.

Typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Nickel Alloys (Super-Alloys)

Nickel Alloys (also known as Super-alloys) are a group of high-performance alloys including nickel, iron-nickel and cobalt-alloys which feature a very special range of mechanical properties.

This group of materials can withstand extremely high operating temperatures and still retain their stiffness, strength and dimensional stability even when approaching their melting point. These characteristics are particularly well suited to additive manufacturing oil and gas applications as well as 3d printing aerospace components parts and assemblies

Additionally, Nickel-alloys offer even more advantages when it comes to corrosion resistance and resistance against oxidation. This makes them the ideal solution for parts and components used within the chemical, petrochemical and oil and gas industries where they are likely to be exposed to harsh chemicals, liquids and fuels or be open to contamination from natural elements such as salt and seawater.

Titanium Alloys

Titanium alloys contain a mixture of titanium and other chemical elements to create a material that has very high tensile strength, toughness and is capable of withstanding high temperatures.

Titanium alloys are lightweight (similar to aluminium) and have excellent corrosion resistance characteristics too. The material is particularly well suited to additive manufacturing titanium aerospace parts due to its high rigidity, heat resistance and relative light weight

As well as fulfilling the needs of many Aerospace, Space, Defense, Oil and Gas and high end Automotive applications, 3d printing metal titanium alloys are widely used within the medical field for the production of both dental and orthopaedic implants

Scalmalloy®

A high-strength, lightweight alloy containing aluminium, magnesium and scandium

Scalmalloy® is a metal material composition developed by AP Works GmbH (a division of Airbus). Scalmalloy® being a low density material offers high levels of tensile strength, high levels of ductility and has excellent corrosion resistance too exhibiting similar characteristics to Titanium Ti6Al4V at room temperature.

Just a few details to fill in...