Tooling, Fixtures and Metal Part Replacements

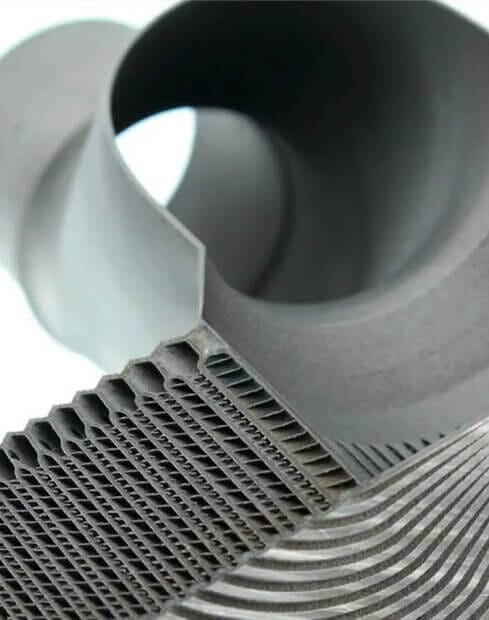

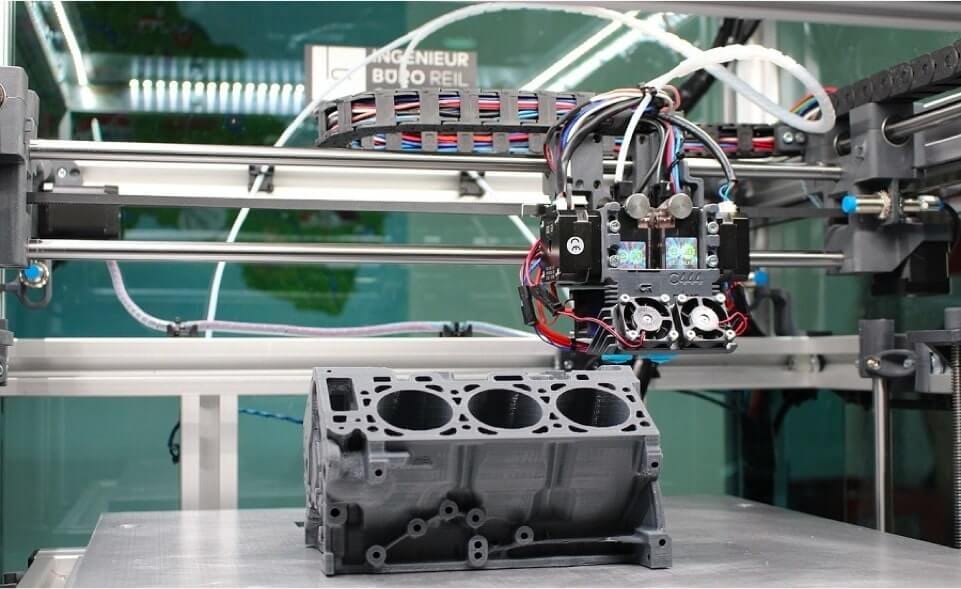

If you need parts made from composites materials, our Markforged Mark2 system and materials could provide the answer. Similar to FDM technology, Markforged use an additive manufacturing material extrusion process to combine one or more separate materials together within the same build. Taking a base composite material like Onyx™, a micro carbon fibre filled additive manufacturing nylon producing parts with strength, chemical resistance and almost flawless surface finish, Onyx™ can be printed on its own or can be reinforced with continuous fibres to create aluminium-strength parts

Onyx™

Flexural Strength: 71 MPa

Onyx is a micro carbon fiber filled nylon. It’s 1.4 times stronger and stiffer than ABS and can be reinforced with any continuous fiber. Onyx sets the bar for surface finish, chemical resistivity, and heat tolerance

Onyx™ ESD

Flexural Strength: 83 MPa

Onyx ESD is an ESD-safe micro carbon fiber filled nylon composite

base material with similar mechanical properties and surface finish

to Markforged Onyx. It is static-dissipative and reinforceable with

continuous fibers to achieve up to 10x strength compared to existing

ESD-safe plastics

Onyx™ FR

Flexural Strength: 71 MPa

Onyx FR is a flame-resistant variant of Onyx designed for use in applications where parts must be non-flammable. The material earned a UL Blue Card, and is considered V-0 (self extinguishing) at thicknesses greater than or equal to 3mm. It can be reinforced with any Continuous Fiber and is compatible with industrial composite 3D printers

Nylon

Flexural Strength: 50 MPa

Nylon White parts are smooth, non-abrasive, and easily painted. They can be reinforced with any continuous fiber and work best for non-marring work holding, repeated handling, and cosmetic parts.

Carbon Fibre

Flexural Strength: 540 MPa

Carbon Fiber has the highest strength-to-weight ratio of our reinforcing fibers. Six times stronger and eighteen times stiffer than Onyx, Carbon Fiber reinforcement is commonly used for parts that replace machined aluminum

Fibreglass

Flexural Strength: 200 MPa

Fiberglass is our entry level continuous fiber, providing high strength at an accessible price. 2.5 times stronger and eight times stiffer than Onyx, Fiberglass reinforcement results in strong, robust tools

HSHT Fibreglass

Flexural Strength: 420 MPa

High Strength High Temperature (HSHT) Fiberglass exhibits aluminum strength and high heat tolerance. Five times as strong and seven times as stiff as Onyx, it’s best used for parts loaded in high operating temperatures.

Aramid Fibre (Kevlar®)

Flexural Strength: 240 MPa

Kevlar® possesses excellent durability, making it optimal for parts that experience repeated and sudden loading. As stiff as fiberglass and much more ductile, it can be used for a wide variety of applications.

Just a few details to fill in...